Updated 2 weeks ago

Buyer's Guide | Choosing the Right Self-Cleaning Public Toilet

contact

1) Market Snapshot and Buyer Priorities

Across transport hubs, parks, campuses, construction sites, and pop-up events, the Self-Cleaning Public Toilet has moved from pilot projects to a mainstream solution. Operators are embracing automated sanitation to reduce closures, stabilize staffing, and deliver a consistent level of hygiene at any hour. The real decision, however, isn't simply "self-cleaning or not." It's about matching technology and capital to site realities - peak traffic, accessibility goals, climate conditions, and sustainability targets - without creating friction for visitors.

Success metrics vary by organization, but the themes are clear:

• Outcomes that count: predictable cleanliness, high uptime, low complaints, safety, and an intuitive user journey.

• Typical locations: train and bus stations, civic green spaces, stadiums and arenas, seasonal festivals, construction compounds, and university quads.

• Stakeholders: municipal teams, facility managers, venue operators, developers, and event producers.

• Performance signals: wait times, uses per hour, cleaning cycles completed, fault alerts, water and chemical consumption, and cost per use.

2) What "Self-Cleaning" Really Means

A self-cleaning toilet rinses and sanitizes itself after someone leaves or on a set schedule. Good systems measure out the right amount of cleaner and use sensors and safety checks so it gets truly clean without putting anyone at risk.

Core capabilities

• Automatic cleaning: focused rinses of the bowl and floor, cleaning the spray nozzles, and sanitizing things people touch.

• Smart safety: sensors to know when the stall is empty, locks while cleaning, and alerts when supplies run low or something isn't working.

• Odor control: active extraction, carbon filtration, and airflow paths that move fresh air from clean zones toward exhaust.

• User safety: visible cycle indicators, emergency stop and manual overrides, and interlocks to prevent entry during a cycle.

• Remote visibility: telemetry dashboards reporting status, consumables, and service needs to cut guesswork and response time.

3) Self-Cleaning vs. Conventional Public Toilets

Automation shifts cost curves and service intervals. A clear view of trade-offs supports ROI and policy design.

• Hygiene consistency: validated cycle logs and contact times versus manual variability and limited traceability.

• Labor model: redeploy staff to exception handling and periodic deep cleans versus continuous janitorial presence.

• Throughput: tighter post-occupancy turnover (e.g., 30 - 90 s) versus multi-minute manual resets.

• Resource use: metered dosing (flow/level verified) versus unmetered application risk.

• UX: deterministic cleanliness with occupancy/lockout signaling versus ad hoc conditions.

• TCO: capitalized equipment costs balanced by reduced OPEX, fewer service interruptions, and measurable uptime gains.

4) Selection Criteria: Align System to Site Demand

Start with peak demand. If your busiest hour is covered, the rest falls into place. From there, audit infrastructure and constraints.

• Demand curve: uses per hour and per day, weekday/weekend shifts, and surge loads during events or game day.

• Utilities: power availability and quality, mains water and wastewater tie-in (or tanks for off-grid), and space for service vehicles.

• Climate and exposure: insulation, freeze protection, heat rejection, humidity control, and sun/rain/wind exposure.

• Accessibility: local code compliance, wheelchair maneuvering clearances, ramps, handrails, and readable signage.

• Durability: vandal resistance, tamper-proof hardware, and materials that survive frequent cleaning and public use.

• Integration: payment or access control where relevant, occupancy guidance, telemetry, and facility management system links.

5) Design and Material Choices for Hygiene and Longevity

Construction details shape perception and life-cycle costs. Favor non-porous surfaces and detailing that resists grime and biofilm.

• Surface materials: non-porous, antimicrobial; rated for repeated chemical cleaning.

• Envelope: water-resistant floor/wall assemblies; impact-rated panels; anti-graffiti finish.

• Detailing: sealed seams; coved/rounded transitions; low-crevice design.

• HVAC/vent: defined intake/exhaust; odor purge paths; thermal comfort control.

• Lighting/UX: uniform illumination; occupied/vacant indicators; wayfinding graphics.

• Audio: optional speakers for PA or ambient sound.

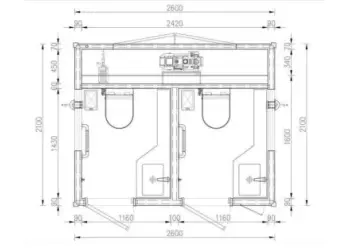

6) Product Spotlight: Twin Compartment Portable Restroom (T-BOX RS-W2 / T-BOX-U-two)

For compact, event-ready deployments, the T-BOX-U-two (also referenced as T-BOX RS-W2) delivers two unisex stalls plus a dedicated equipment room. It is not a Self-Cleaning Public Toilet by default, but it pairs well with sensor-driven cleaning schedules and standardized sanitation protocols to maintain dependable hygiene in a small footprint.

✅ Highlights that drive performance

•Auto-clean ready: T-BOX RS-W2 can be equipped with an add-on automatic cleaning module; a 30-second auto-sanitization cycle achieves a sterilization rate ≥99% and reduces manual cleaning labor costs by up to ~80%.

•Throughput: two independent stalls plus dual basins shorten queues; with rapid 30-second auto-clean, typical peak capacity across both stalls can reach ~40–60 users per hour (assumes 1–2 minutes dwell per user).

•Durability: tile floor, aluminum-honeycomb roof, and carbon-crystal walls clean quickly and resist wear for high-cycle deployments.

•Weather-ready: fluorocarbon aluminum composite cladding resists corrosion and UV for outdoor reliability.

•Comfort and hygiene: Gree 1.5P centralized HVAC stabilizes climate; ESANITEC fixtures support fast, thorough cleaning; optional auto-clean module maintains consistent hygiene between uses.

•Clarity for users: LED occupancy cues and in-ceiling audio provide clear guidance and reduce missteps.

•Off-grid capable: onboard tanks and an ~1 L/flush air–water system conserve resources and minimize service frequency.

•Right-sized capacity: ~800 uses per water load; tanks ~1.0/1.1 m³ support multi-day events depending on traffic.

•Compact footprint: 2.6 x 2.1 x 2.95 m; ~2,000 kg for transport and siting.

•Best-fit scenarios: festivals, public parks, pop-ups, and tight urban sites seeking eco-conscious sanitation without heavy infrastructure.

✅ Capacity planning and sizing

Right-size to your peak.

•Lines: aim for no more than a 3 - 5 minute wait at busy times by adding enough doors for the crowd.

•Tanks: about 1 liter per flush and roughly 800 uses per fill - plan refills and pump-outs so they don't interrupt the event.

•Space: smaller units fit more in less space; keep paths wide and accessible to avoid jams.

•Backup: more than one unit means you can handle maintenance, surprises, and rushes.

•Smart ops: sensors and occupancy signals help you time cleaning, restocking, and pump-outs.

✅ Install and site setup

• Groundwork: level bases, secure anchors, safe entries/exits, and ADA-friendly ramps and clearances.

• Power: give HVAC, lights, sensors, and automation their own circuits; protect from bad power.

• Water: pick mains or onboard tanks; add filters and backflow protection as required.

• Waste: set pump-out times and follow local rules for storage, transport, and approvals.

• Connectivity: provide network routes for telemetry and status reporting; integrate with asset management platforms.

• Safety measures: non-slip surfaces, emergency lighting, protected electrical enclosures, and clear evacuation routes.

7) Operations, Maintenance, and Safety

Proactive routines keep a Self-Cleaning Public Toilet clean, safe, and online.

• Cleaning cadence: align auto cycles with occupancy patterns; top up with rapid post-use wipe-downs where needed.

• Consumables control: track usage rates for water and disinfectant; maintain buffer stock of filters, seals, and pumps.

• Reliability checks: calibrate sensors, test HVAC performance, confirm valve integrity, and examine structural fixings.

• Safety first: validate lockouts during cleaning, ensure signage is unmistakable, and run emergency drill tests monthly.

• Resilience against misuse: choose impact-resistant panels, concealed fixtures, and hardware that deters tampering.

• Team readiness: standardize SOPs, refresh training quarterly, and store service records in a central, searchable platform.

8) Budgeting, Sustainability, and Procurement Checklist

Make procurement a framework, not a guess.

• TCO modeling: include capex, power and water, chemicals, staffing, and avoided downtime for fair comparisons.

• Efficiency wins: near-1 L flushes, automated dosing that reduces chemical use, and HVAC tuning that cuts energy bills.

• Environmental wins: compliant wastewater practices, long-life repairable materials, and defined recycling or take-back.

• Partner assurance: solid warranties, fast parts supply, local service coverage, and complete regulatory approvals (UV-C as needed).

• Smart purchase plan: clear capacity targets, water/waste strategy, accessible design, connected telemetry/integration, structured training, smooth handover, and stocked spares.

Final Thoughts

Modern public sanitation succeeds when simplicity meets rigor. Size for peak loads, design for fast cleaning, and demand clear safety signals and data visibility. If a fully automated approach isn't feasible, a robust twin-compartment unit like the T-BOX-U-two, combined with sensor-led cleaning and thoughtful maintenance, can meet expectations for hygiene, accessibility, sustainability, and uptime - without overextending your infrastructure.