Updated 3 weeks ago

What Makes a Heat-Resistant Modular Toilet Thrive in Heat Environment?

contact

Heat-Resistant Modular Toilet

Scorching sun, radiant equipment, and long heat waves can turn standard portable restrooms into weak links. Plastic skins soften, door frames go out of square, and lingering odors signal bacterial growth in warm interiors. A heat-resistant modular toilet is built to thrive where ordinary cabins fail. Using fire-rated insulated enclosures, rigid steel framing, and durable ceramic and stainless fixtures, these systems protect users, stay cleanable, and keep working in places like refineries, steel plants, desert construction, power-generation yards, and wildfire response camps. For operators that depend on uptime, they offer more than basic life safety: better comfort, longer service life, and flexible configurations suited to both rapid deployments and semi-permanent installations. Increasingly, specifiers group them under the broader category of Mobile Sanitation Units designed for extreme environments.

What Is a Heat-Resistant Modular Toilet?

A heat-resistant modular toilet brings reliable performance to hot, high-risk environments. It's a coordinated system - structure, envelope, fixtures, and airflow aligned for safety and durability.

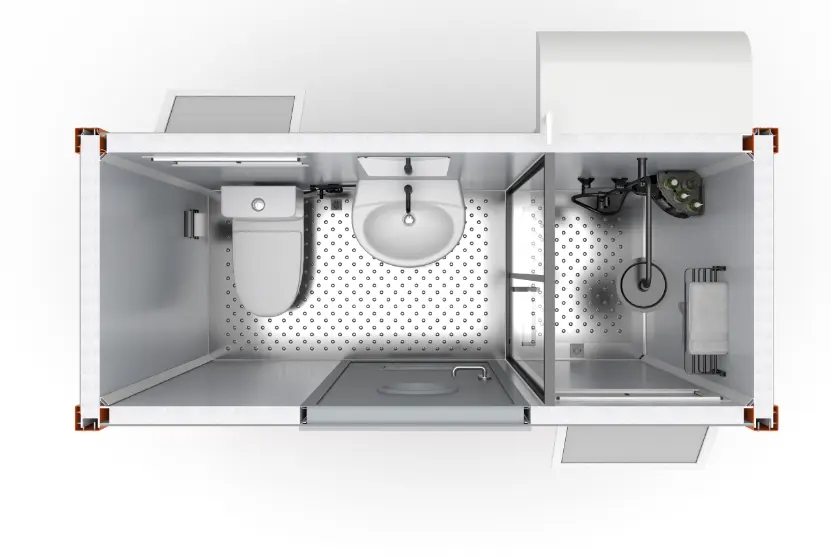

Core elements typically include:

• Frame: Powder-coated carbon steel or stainless 304/316 for stiffness and corrosion resistance under heat.

• Panels: Steel sandwich with rock wool or PIR cores to slow heat and limit flame spread.

• Heat-resilient flooring: 304 stainless flooring that stays flat, sheds water, and stands up to chemicals and heavy footfall.

• Fixtures: Ceramic toilet and pedestal basin for hygiene, stainless steel faucet and flush gun for longevity, and in shower-equipped layouts, an 8 mm tempered glass partition and heat-rated water heater.

• Ventilation and access: A louvered steel door and top-hung window to sustain crossflow; mechanical fans added as occupancy or heat load increases.

• Thermal seals: Heat-resistant gaskets and intumescent seals at openings to maintain envelope integrity and suppress smoke migration.

Compared with traditional portable toilets, these units deliver greater thermal stability, safer materials, and markedly better ventilation and user comfort. They are heavier and costlier upfront, and transport and anchoring require more planning, but the trade pays off where heat is a constant threat. In the marketplace you'll see variations labeled as heat-proof modular toilets, fire-resistant portable restrooms, or thermally insulated mobile bathrooms - each tuned to specific risk profiles. Many vendors now position these solutions within their Mobile Sanitation Units portfolio to signal mobility plus industrial-grade performance.

Why Choose a Heat-Resistant Modular Toilet

• Fire-safety detailing supports compliant, safer operations

• Heat-stable materials extend service life and reduce replacements

• Insulation and ventilation reduce reliance on powered cooling

• High-SRI exterior finishes or shading lower radiant heat gain

• Durable, non-porous surfaces cut chemical use and cleaning time

• Modular scalability minimizes waste and right-sizes to your site

These strengths make them a sensible choice for oil and gas terminals, smelting and foundry operations, logistics hubs, highway and transmission builds, remote tourism sites in hot climates, outdoor events, and emergency operations centers. If your sanitation plan must ride out weeks of high temperatures, these Mobile Sanitation Units provide the resilience standard portables can't match.

An Example Configuration Built for Heat

• Frame: Steel with electrostatic epoxy/polyester powder coat for corrosion resistance and long-term rigidity.

• Walls: Steel-faced panels insulated with rock wool to limit conduction and enhance fire rating.

• Floor: 304 stainless sheet for rapid cleanup and resistance to moisture, chemicals, and abrasion.

• Sanitaryware: One ceramic toilet and one ceramic pedestal basin for durable hygiene.

• Access and airflow: Louvered steel door and a top-hung window; mechanical fans available for high-occupancy or low-wind locations.

• Accessories: LED ceiling light, clear signage, stainless steel faucet, stainless flush gun, 8 mm tempered glass shower partition, stainless three-head shower set, and a water heater rated for high temperatures with automatic cutoffs.

• Thermal detailing: Heat-resistant gaskets and intumescent seals at door and window interfaces; optional reflective exterior coatings to limit solar gain.

For industrial use, packages can be specified with higher fire ratings, boosted ventilation, expanded holding tanks (for example, 300 - 600 L), and quick-connect utility interfaces that shorten commissioning time. This configuration suits construction compounds, scenic attractions, festival grounds in hot regions, and temporary utility camps where both toilet and shower service must continue despite heat.

How to Choose the Right Unit

•Site thermal profile: Document peak ambient temperature, duration of exposure, and any radiant sources such as furnaces, generators, or boilers. Select panel thickness and fire class in line with those risks.

•Choose panels and fire ratings that match the heat risk - don't under-spec near hot work.

•Double-check local rules for fire, airflow, electrical protection, and accessibility. Ask your AHJ whether NFPA 101 or EN 13501 is the benchmark.

•Build for peak: A 50-person crew needs several stalls and a shower unit, plus hot-water recovery that handles back-to-back showers.

•Plan waste early: Mains tie-in, tanks, or vacuum - set slopes, outlet sizes, and pump-out timing to keep lines clear and odor-free.

•Line up utilities: Confirm power (grid/genny/solar) and water pressure. Pick heaters with safety cutoffs and enough recovery for rush periods.

•Material resilience: Consider UV exposure, dust, salt air, and chemical splash. Stainless steel and ceramic usually deliver the best mix of cleanliness, durability, and lifecycle cost.

•Ventilation and comfort: Size louvers and fans to occupancy and climate. Add shading or high-SRI coatings where solar loading is severe.

•Mobility and footprint: Confirm crane or forklift access, anchoring points, clearances, and routes for relocation. Detachable modules simplify redeployment in phased builds.

•Wayfinding and appearance: Choose durable finishes, non-slip flooring, and bright, intuitive signage to support safety and round-the-clock use.

Maintenance and Cleaning for Heat Longevity

Even the best materials need routine care to maintain heat performance.

•Daily to weekly cleaning: Use non-corrosive cleaners on stainless floors and ceramic fixtures. Clear hair and debris from traps, and wipe glass and partitions to prevent soap film.

•Odor management: Inspect door seals and plumbing connections, service fans and louvers, and keep holding-tank pump-outs on schedule.

•Envelope resilience: After each thermal cycle, inspect seams, penetrations, and seals; install heat-rated gaskets and intumescent compounds; quickly close any pathway that could pass smoke or heat.

•Service checks under load: At operating temperature, test heater safety cutoffs; confirm fixtures show no heat-induced deformation or leakage; ensure lighting and emergency signs meet ambient temperature limits.

•Aggressive corrosion management: Remove abrasive dust and salts with rinse-downs; repair any coating nicks or scratches promptly; specify epoxy primers with polyurethane topcoats in zones with elevated corrosion exposure.

Quick troubleshooting:

❓Interior too warm? Verify fan airflow and power, add temporary shade, or apply reflective topcoats.

❓Slow drainage? Clean traps, verify outlet alignment, and check S-bends for debris.

❓Persistent odor? Inspect vent lines, tank seals, and floor drains for blockages or dry traps.

How They Compare to Traditional Portable Toilets

Thermally rated gaskets, fire-resistant wall construction, and steel framing deliver shape retention and low emissions. Plastic cabins show softening, warping, and odor release under long heat exposure.

•Durability: Industrial frames and insulated panels extend service life and reduce replacement cycles. • Comfort/hygiene: Insulated, ventilated shell with ceramic and stainless surfaces = fast, thorough cleaning and better experience.

•Deployment: Modules add showers, ADA layouts, utility tie-ins; plastic portables suit short mild events, not industrial heat.

•Economics: Upfront premium is compensated by reliability - fewer failures and less stoppage bring lifecycle costs in line, particularly where heat loads are high.

When heat defines your operating environment, upgrading to heat-resistant modular toilets is a practical, risk-aware choice. As part of a broader strategy using Mobile Sanitation Units, these systems combine safety, comfort, and compliance-ready construction to keep people productive when temperatures soar. Whether you need a single stall for a remote crew or a multi-bay suite with showers for an industrial shutdown, modern heat-resistant modules provide durable, hygienic infrastructure that moves with your project and stands up to the climate.